INDUSTRY 4.0

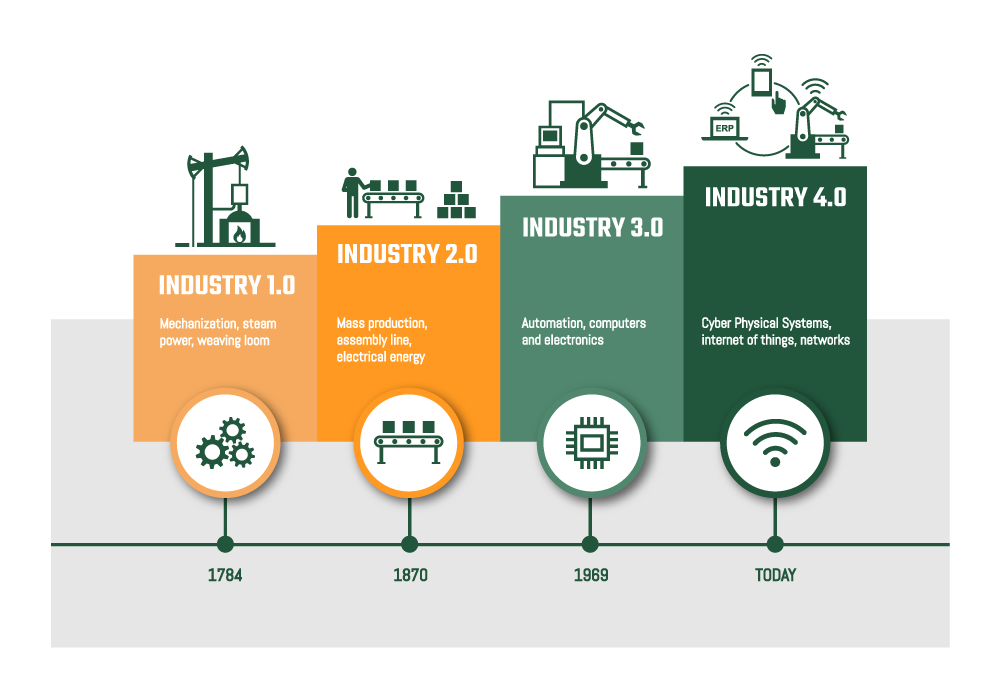

While the first industrial revolution began in the early 1770s focussed on machines running on steam and water. Industry 2.0 initiated by the introduction of electricity that further raised productivity. Industry 3.0 initiated with the introduction of computers and automation by the 1970s.

Industry 4.0 refers to the adoption of technologies like artificial intelligence, augmented reality, internet of things and cloud computing, to create a network of computerized machines able to pass information among each other.

Connected machines will interact, visualize the production

chain, and make decisions automatically and autonomously. The nine main pillars

of industry 4.0 are:

1) Internet of Things – IOT refers to Networking and

connectivity of smart devices that allow smooth and continuous transmission of

data.

2) Augmented Reality - Augmented reality (AR) displays

digital content in the real word through a device, such as a mobile phone or

special eyeglasses.

3) Simulations

5) System Integration With improved system integration,

companies can become more interconnected both externally and internally. This

will result in an agile manufacturing environment allowing real time production

corrections and quick pivots.

6) Cloud Computing As the use of technology and data

sharing at manufacturing companies grows, cloud computing provides scalable

storage and increased computing power. The cloud also improves data

accessibility and integrity, helping to eliminate data silos.

7) Autonomous Systems While the manufacturing industry has

made great strides when it comes to automation over the last few years, there

is still a lot of untapped opportunity. Collaborative robots are designed to

fill the gaps between traditional robots and human workers and open up new

areas for automation.

8) Cybersecurity As connectivity increases, the risk

of a potential cyberattack grows alongside it. Any security breach could damage

multiple areas of the business, from supply chain to operations. It’s

absolutely critical that companies prepare and protect their information

systems and production lines from cyberthreats.

Big Data Analytics The common theme among all of these pillars and new technologies is data collection and analysis. There are massive amounts of untapped data in the manufacturing industry, and we are just beginning to scratch the surface.

Good bro....

ReplyDeleteVery nice bro... But can u please manage content to zoom out.. i am not able to study whole

ReplyDeleteyes I will surely do it

Delete